Hospitals and diagnostic networks operate under rising pressures. They face increasing sample volumes, complex workflows, staffing shortages, and expectations for faster clinical results. These challenges push leaders to rethink how modern laboratories function. Over the past decade, laboratory automation has grown steadily, but many labs still rely on human technicians for the most basic yet critical task: sample transport. This gap creates delays, inconsistencies, and workflow bottlenecks.

Today, autonomous mobile robots in clinical labs close this gap by delivering a new level of speed, accuracy, and consistency. AMR for laboratory sample transport adds mobility, intelligence, and reliability to the automation landscape. Hospitals now view AMRs as essential tools that support high-volume laboratory environments.

Laboratory Automation Moves Beyond Static Systems

Traditional Automation Lacked Mobility

Laboratories have used analysers, liquid handlers, and robotic arms for years. These tools automate plate handling, sample preparation, and specific test processes. However, these instruments stay fixed in one place. They cannot move samples between rooms, analysers, or departments.

This limitation forces lab technicians to walk between stations continuously. It slows down workflow and prevents laboratories from achieving a truly end-to-end automated ecosystem. Many hospitals tried to scale traditional automation, but the static nature of these tools still left sample transport dependant on human effort.

Autonomous Mobile Robots in Clinical Labs Fill the Mobility Gap

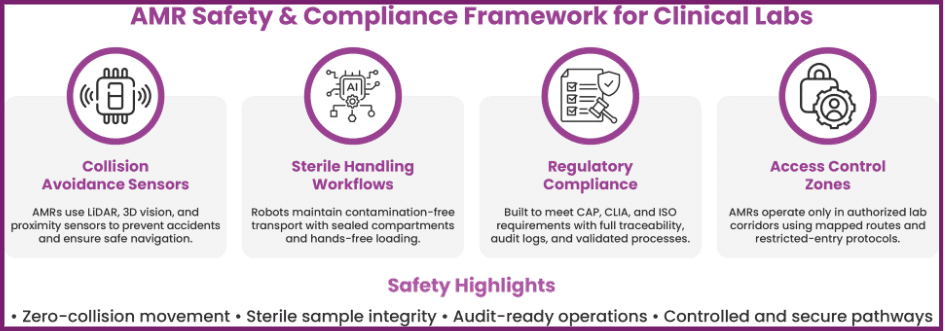

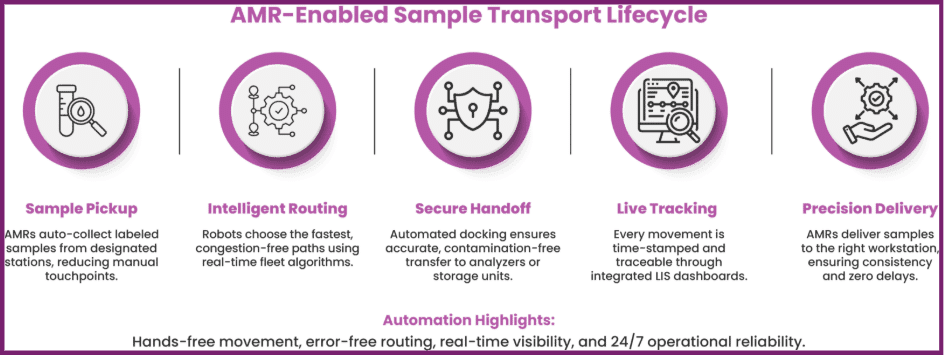

The introduction of autonomous mobile robots in clinical labs solves this problem. AMRs navigate hallways, tight spaces, and multi-room layouts with precision. These robots move vials, racks, consumables, and test trays without requiring manual assistance.

They operate as part of automated sample transport systems that create fluid movement across different lab functions. By bridging the physical gap between instruments, AMRs enable continuous, uninterrupted workflows. Laboratory automation becomes far more powerful when mobility enters the equation, and AMRs provide that mobility with intelligent routing and built-in safety features.

Read More – Laboratory Information Management System – Ezovion

Key Benefits of AMR for Laboratory Sample Transport

With laboratory automation rapidly evolving, AMR for laboratory sample transport has become a game-changer for modern clinical labs. These autonomous mobile robots in clinical labs streamline operations, minimise manual errors, and deliver measurable performance gains across every stage of diagnostic workflows.

• AMRs Improve Lab Turnaround Time by Eliminating Delays

Clinical labs must consistently improve lab turnaround time automation to meet hospital performance expectations. Technicians lose valuable minutes each time they walk across the facility to move samples. Over a day, those minutes accumulate into hours of lost productivity.

AMRs eliminate this inefficiency. They maintain constant motion, transport samples instantly after preparation, and run tasks without breaks. Hospitals report remarkable improvements in TAT when they adopt automated sample transport systems. When AMRs handle logistics, staff focus on analytical tasks and quality control instead of repetitive transport activities.

• AMRs Reduce Human Error and Strengthen Sample Integrity

Manual handling introduces risks such as mislabelled samples, temperature exposure, or accidental mix-ups. These errors compromise diagnostic accuracy. AMRs eliminate variability by executing precise, repeatable movement. They keep samples in ideal conditions and follow validated workflows.

This consistency supports robotic workflow automation in hospitals because AMRs standardise execution across all shifts. Laboratories trust AMRs because they preserve sample integrity, reduce interruptions, and support seamless chain-of-custody management.

• AMRs Increase Flexibility Through Mobile Robot Orchestration in Labs

Traditional automation demands rigid lab layouts. AMRs lift those limitations. Mobile robot orchestration in labs allows robots to adapt to changes, support new analysers, or handle new workflows without reconfiguring infrastructure. This flexibility lets hospitals expand sections, redesign stations, and scale capacity without overhauling older systems.

AMRs also support next-gen robotics for medical laboratories by connecting multiple automation islands. They create a network of machines, data systems, and technicians working in harmony.

• AMRs Improve Staff Safety and Reduce Physical Burden

Technicians walk several miles per shift transporting racks and containers. This creates fatigue, repetitive strain, and potential exposure to infectious materials.

AMRs reduce these risks by handling routine transport work. Staff stay focused on analytical tasks while robots ensure safe, contactless movement. Hospitals experience improved ergonomics and higher staff satisfaction because AMRs remove physically demanding activities from daily operations.

Also Read – Benefits of Using LIMS -Ezovion

Integrating AMRs Into Modern Laboratory Automation

As clinical workloads grow, hospitals need smarter, faster, and more reliable transport processes. AMRs bridge this gap by integrating directly into laboratory automation workflows and transforming how samples move across departments.

• Mapping Transport Workflows for AMR Deployment

Hospitals start by analysing workflows to identify bottlenecks. They track sample movement across pre-analytical, analytical, and post-analytical stages. This reveals where manual transport slows operations.

Once mapped, automated sample transport systems take over the most time-sensitive routes. Labs often begin with a high-volume route before expanding AMR deployment across the entire facility.

• Choosing the Right AMRs for Complex Laboratory Workflows

Hospitals evaluate several factors before choosing AMRs:

- Navigation capabilities

- Payload type

- Battery autonomy

- Safety sensors

- Integration compatibility with LIMS

AMR integration with LIMS systems becomes crucial because laboratories rely on digital tracking. AMR-LIMS communication updates sample locations in real time and supports traceability. When hospitals adopt AMR integration with LIMS systems, they achieve fully coordinated robotic workflow automation in hospitals.

• Running Pilot Programs to Validate Performance

Most hospitals begin with pilot programs to test efficiency gains. They measure improvements in TAT, reduction in manual handling, and accuracy in sample movement. During pilots, teams observe how AMRs improve sample transport efficiency in real operations. These findings justify scaling.

By proving ROI early, hospitals accelerate adoption across units and departments.

• Overcoming Deployment Challenges

Hospitals consider layout constraints, multi-floor travel, Wi-Fi connectivity, and integration with existing automation instruments. They also evaluate staff training requirements to ensure smooth adoption. By planning carefully, hospitals ensure that next-gen robotics for medical laboratories operate without interruptions.

Real-World Use Cases in Clinical Labs

Real-world deployments of AMRs reveal how modern clinical laboratories transform sample movement, efficiency, and continuity of operations.

High-Throughput Diagnostic Laboratories

Large diagnostic labs handle thousands of daily samples. They rely on automated sample transport systems to keep workflows stable. AMRs manage movement between centrifugation, aliquoting, analysers, and storage. This consistent flow helps laboratories improve lab turnaround time automation without expanding labour force.

Teaching Hospitals and Multi-Building Campuses

AMRs travel across buildings to support teaching hospitals where labs spread across wings or floors. Mobile robot orchestration in labs ensures that AMRs avoid obstacles, elevators, and busy hallways while maintaining steady workflow progress.

24/7 Central Laboratory Operations

Night shifts suffer workforce shortages. AMRs support full operations around the clock. They move samples immediately after each processing stage and keep analysers running continuously. This capability demonstrates how AMRs improve sample transport efficiency during low-staff periods.

Also Read – How LIMS Software Improve Lab Efficiency & Accuracy – Ezovion

The Strategic Value of AMRs for Hospital Leadership

Administrators value AMRs for measurable outcomes. Leaders track improvements in throughput, accuracy, and staff utilisation. They also see long-term gains such as modular lab design, scalable capacity, and reduced operational risks.

AMR for laboratory sample transport strengthens resilience in high-volume environments. Hospitals also gain competitive advantage because AMRs enhance reliability and shorten result delivery time.

AMRs Define the Future of Laboratory Automation

Laboratory automation evolves rapidly, and AMRs redefine what is possible. Autonomous mobile robots in clinical labs transform workflows by adding intelligence, mobility, and precision. Hospitals now rely on AMRs to improve lab turnaround time automation, integrate data systems, strengthen sample movement, and elevate diagnostic reliability.

AMR-driven automation allows laboratories to run smarter, faster, and more efficiently. As next-gen robotics for medical laboratories continue to advance, AMRs will shape the future of diagnostic excellence worldwide.